At Kollaborative Work, we don’t sell software. We design and integrate technological solutions only when they genuinely deliver operational value, as part of a strategic roadmap. We integrate useful tools only when they bring results. Our technological solutions are at the service of each client’s success.

- We don’t sell licenses or impose platforms

- We select tools only when they offer real value

- Our solutions adapt to your team—not the other way around

- We support usage, adoption, and continuous improvement

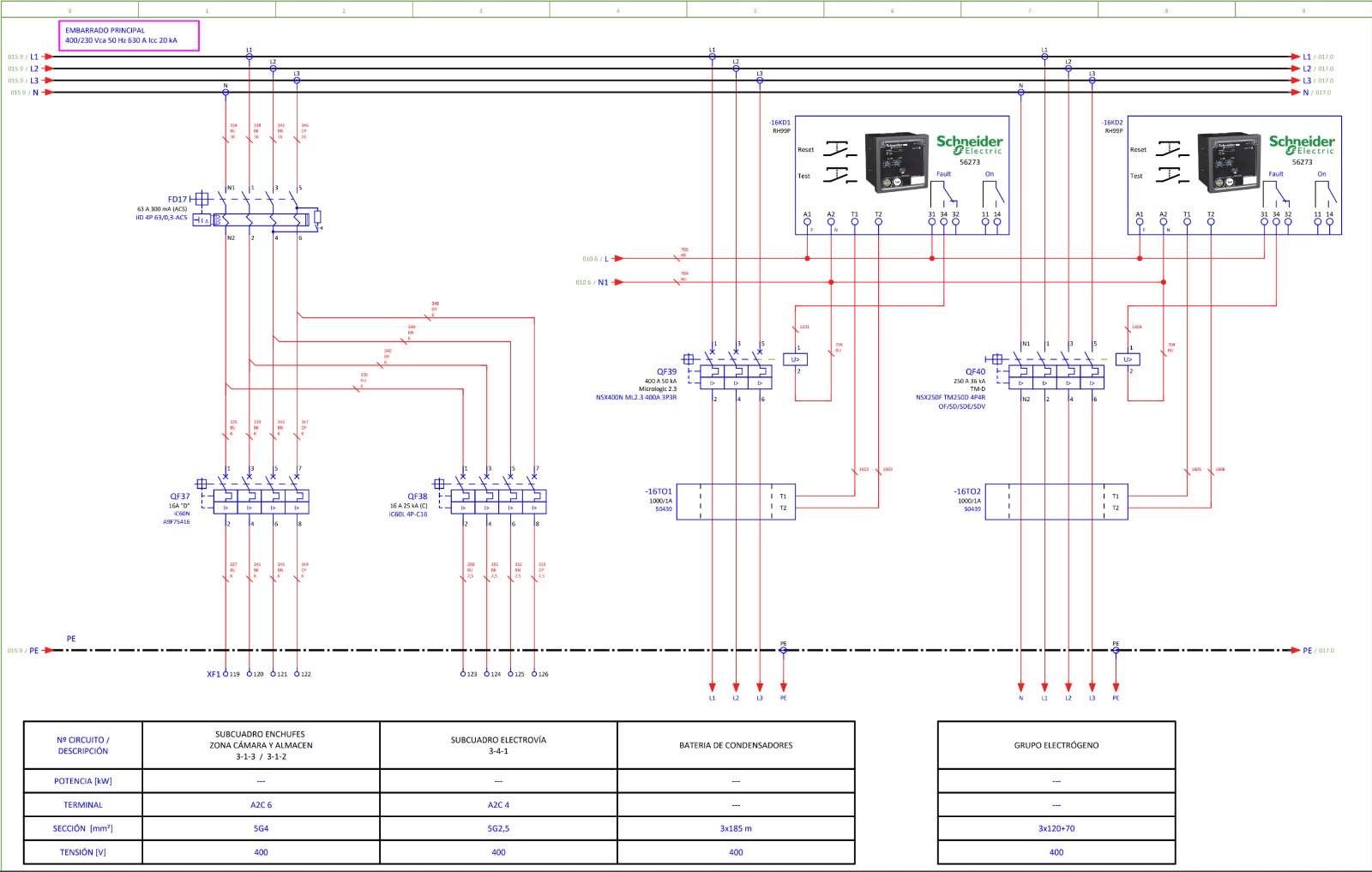

- We write design standards for critical infrastructure

Solutions

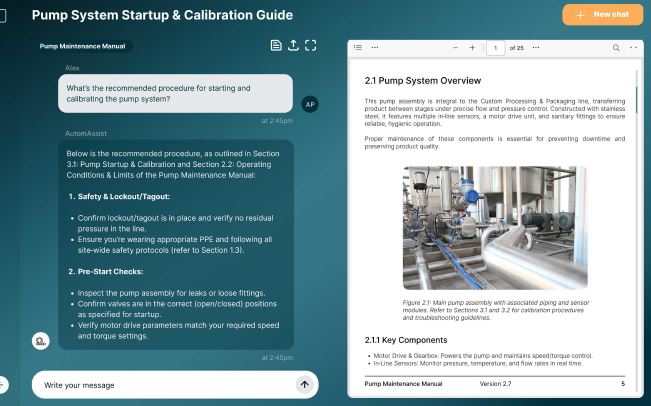

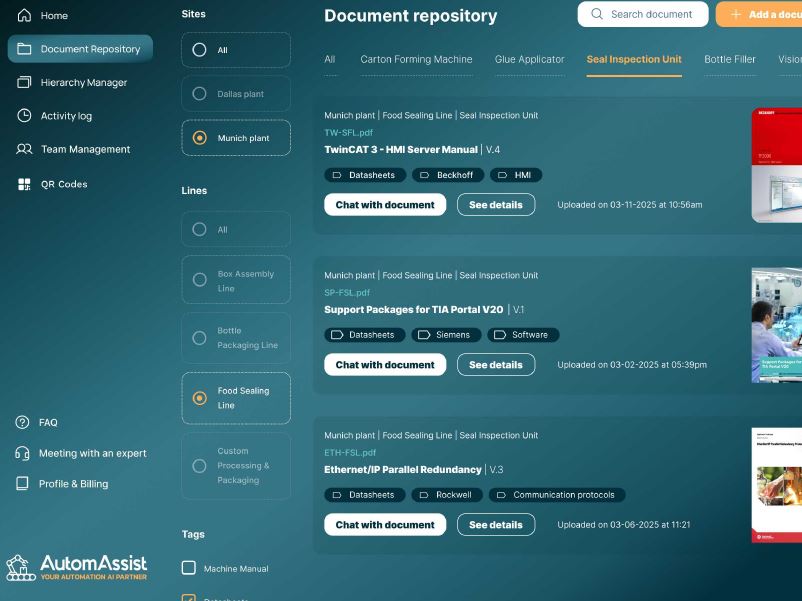

Smart Industrial Document Management

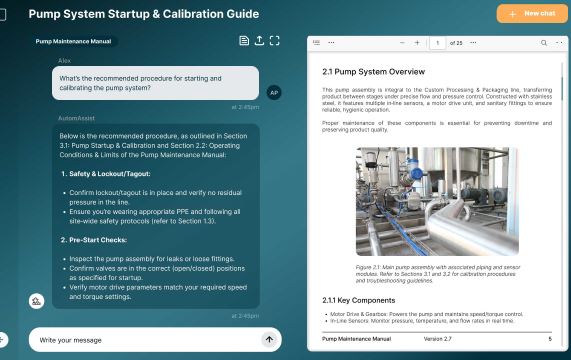

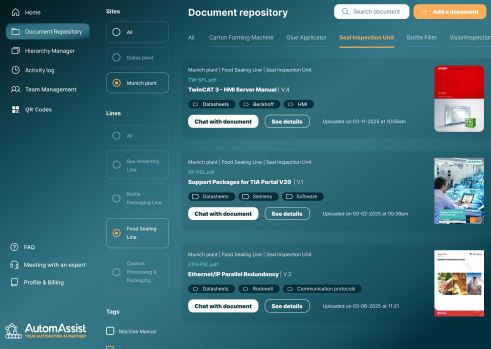

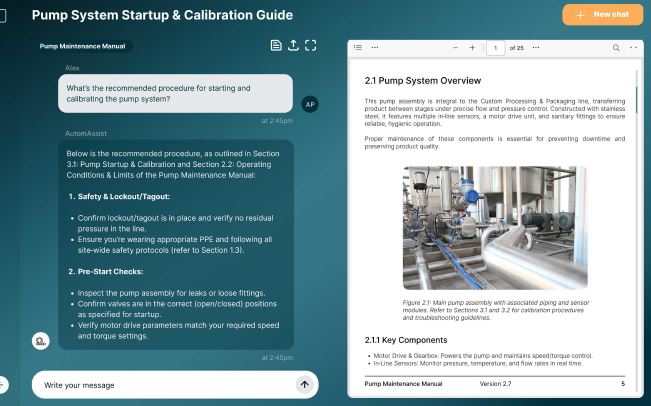

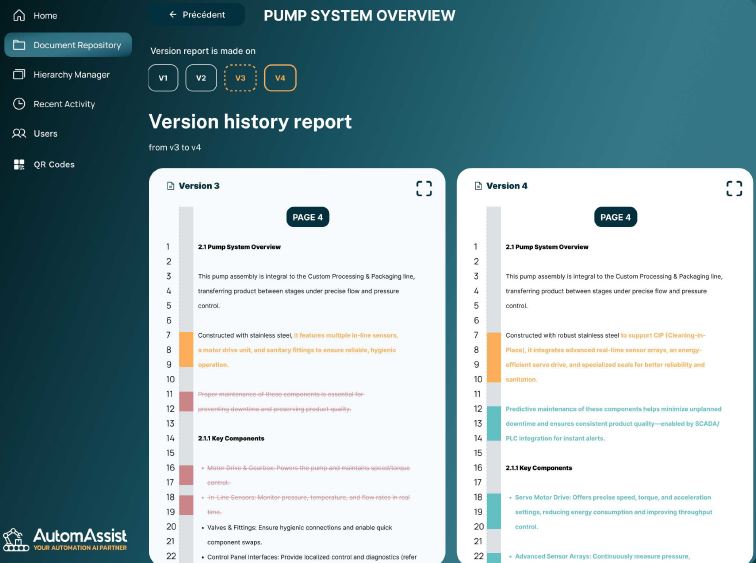

We simplify traceability and access to plant technical documentation with an intelligent system for classification, version control, and permissions.

One of the most common uses of this solution is paperless document traceability. We digitize critical documentation such as maintenance reports or quality procedures, enabling automatic, traceable management that is accessible from anywhere in the plant. This digitalization saves time during audits, prevents information loss, and improves regulatory compliance in demanding industrial environments such as the pharmaceutical or food industries.

Technical Manuals

Centralized and updated access to procedures and operational manuals

Smart Image-Based Document Management

Management of electrical diagrams and technical documentation in graphic formats. Supports scanned technical images (diagrams, plans) and can recognize text via CR/OCR.

Easy Access via Tags, QR or AI

Easy access to documentation using tags or natural language with AI. Compare up to 100 files simultaneously

Access critical plant documentation (manuals, electrical diagrams, scanned blueprints, procedures, and datasheets) from any device. Always version-controlled, organized, and AI-searchable.

- Advanced AI search

- Fast and secure viewing

- Version and permission control

- Secure and manageable (cloud or on-premise)

- Integration with AutomAssist IDM, SharePoint, ChatGPT, Gemini...

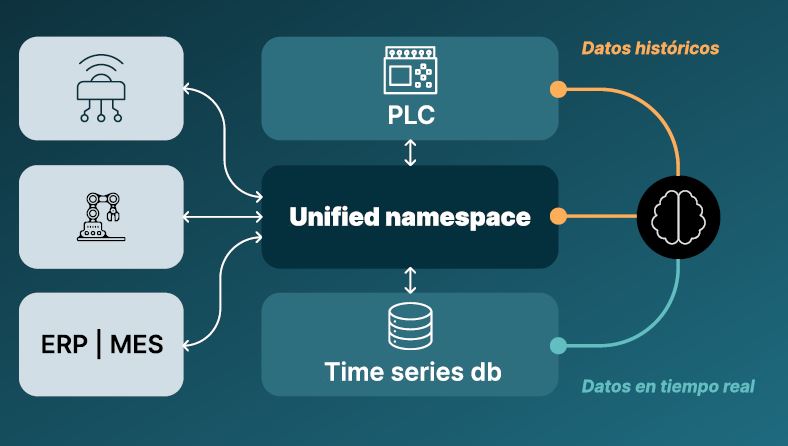

Plant data visualization in natural language

We replace traditional dashboards. Now you can ask in natural language, and AI generates the charts for you.

We democratize access to data: you no longer need technical knowledge to analyze what’s happening in the plant. Just ask a question (“Which line had the most downtimes this week?”) and the system generates the chart. This applies to use cases like OEE optimization, shifts, and alarms—helping you make faster decisions with less analytical burden on staff.

Simple visualization

Clear and structured visualization for plant managers

Automated analysis

Automatic analysis without technical knowledge (Power BI alternative)

Direct connection

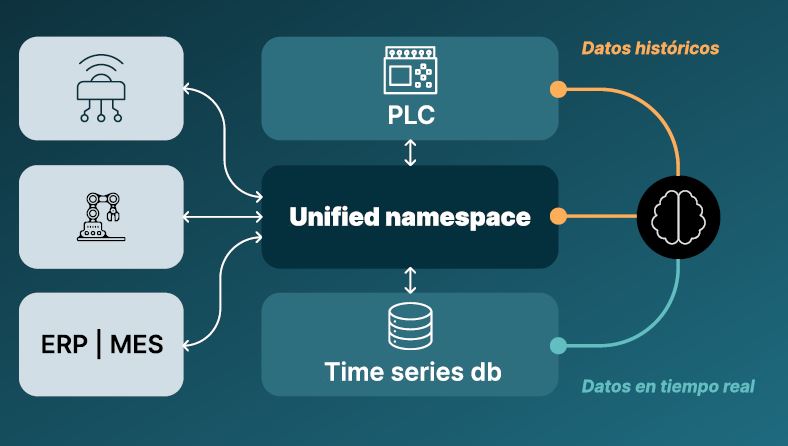

Direct connection to MES, PLC, and ERP systems

Connect your MES, PLC, or ERP systems and access the information without technical knowledge. Data that is understandable, accessible, and actionable. Ideal as a Power BI alternative, with automated access and smart analysis without the need for technical expertise.

- Hierarchical dashboards for managers

- Natural language alerts and analysis

- Integration with SharePoint and corporate environments

- Powered by AutomInsight, Innobox, ePOLCA

Real-Time Plant Data Analysis

Our solution enables plant modernization without replacing existing machinery, thanks to non-intrusive technologies. We capture key signals—such as production, downtimes, or operating conditions—directly from PLCs or dataloggers, without disrupting operations or requiring recertification. This is essential to improve efficiency in environments with legacy or hard-to-adapt technology, especially where process validation is critical, as in the pharmaceutical sector.

Local Data Monitoring

Analyze and process plant data locally, without depending on the cloud or external connections.

Process Optimization and Cost Reduction

Reduce downtimes, improve productivity, and make better decisions based on real-time data captured directly from your equipment.

Flexible Integration and Industrial Connectivity

Compatible with multiple protocols (Modbus, OPC UA, Ethernet/IP...) and client systems such as ERP, MES, SCADA, or BI.

Local data analysis enables real-time data capture and processing directly from equipment, without relying on the internet.

It improves productivity, reduces costs, and integrates seamlessly with industrial systems like ERP, MES, or SCADA

- No internet connection required

- Compatible with many industrial protocols: PLCs, Allen-Bradley, Modbus, OPC UA

- Operational optimization and cost reduction

- 24/7 operation, autonomous and multi-user

- Integration with ERP, MES, SCADA, CMMS, and BI

- Analytics for current production, recipes, shifts, and recipe-based failures

- Datalogger

- Alarm logging

- Preventive maintenance

- Predictive production analysis

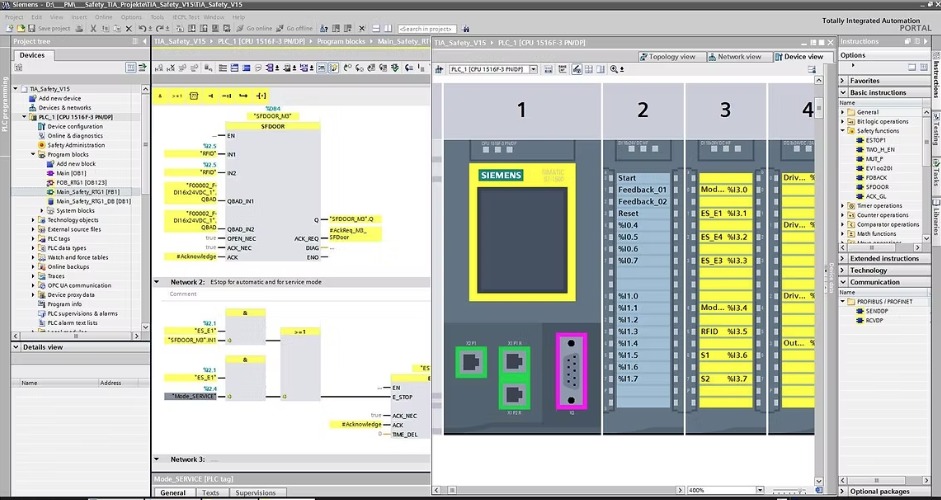

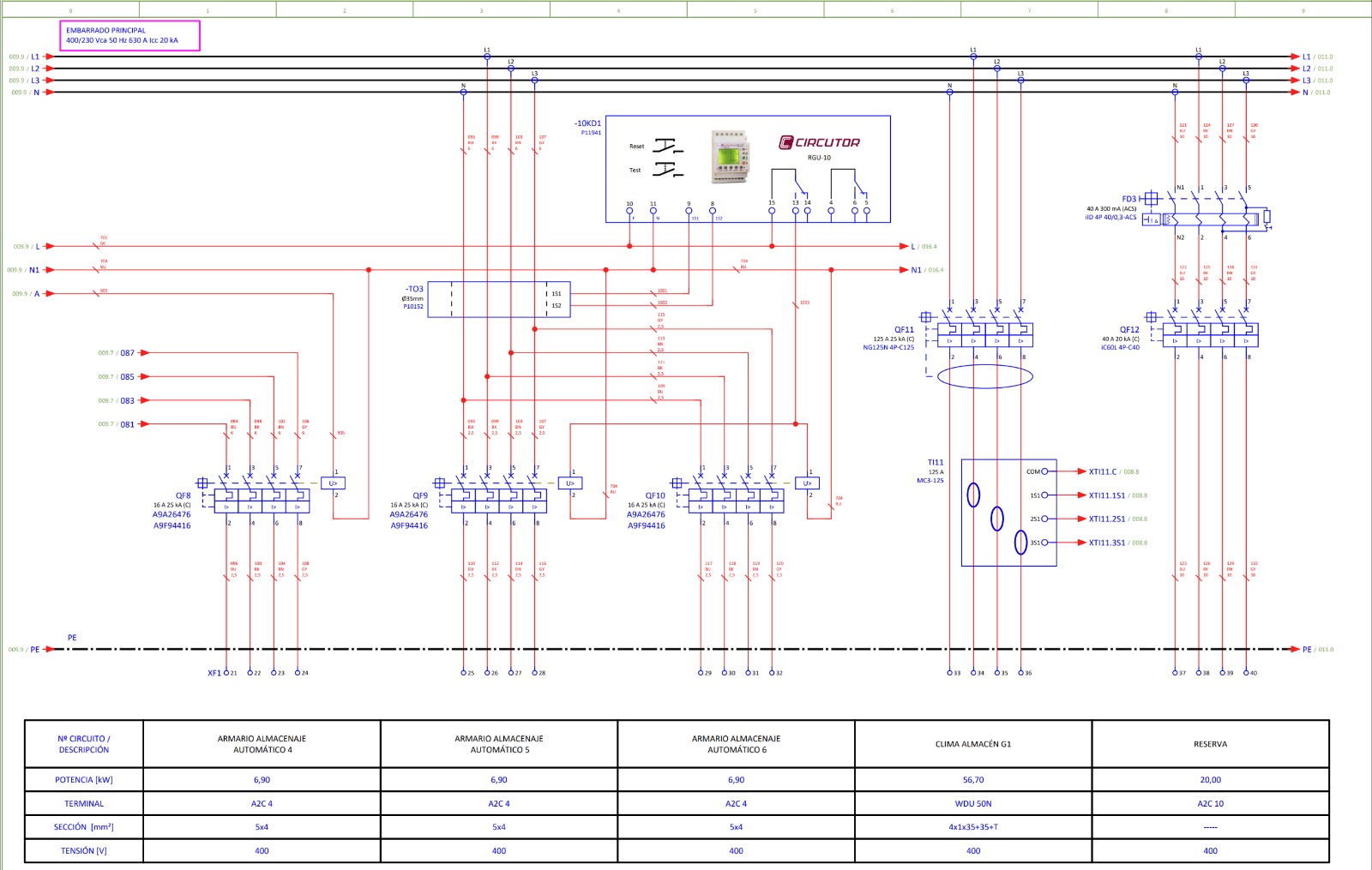

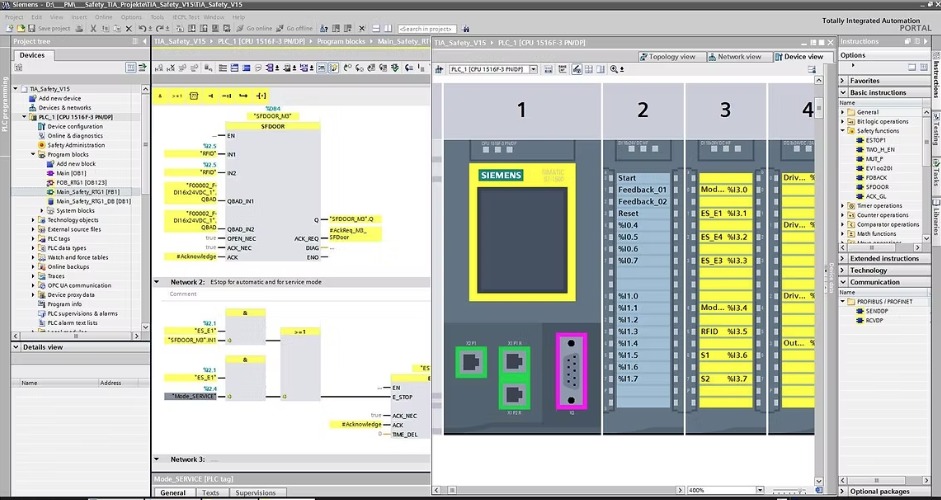

Drafting Design Standards for Engineering

Technical standardization is key in environments where consistency between engineering projects directly impacts operational efficiency. In pharma-veterinary sectors, defining clear criteria for electrical diagrams, naming conventions, programming structures, and technical documentation allows alignment among engineering, maintenance, and suppliers.

This homogeneity speeds up new implementations, simplifies maintenance, and reduces errors—even in multi-line or multi-technology plants. It provides a solid foundation for scalable growth, without depending on individual criteria from technicians or integrators.

Clear and unified technical documentation

We draft standards for electrical diagrams, schematics, bill of materials, and protocols.

Automation homogeneity

We define programming structures (blocks, tags, alarms) to simplify future modifications.

Agility in maintenance and projects

Thanks to a standardized base, any provider or technician can work with less training time.

Provide the plant with coherent and reusable technical criteria, applicable to new projects or modifications.

Reduce ambiguities, errors, and dependencies on external suppliers.

- Improve design and project review efficiency

- Make work easier for suppliers and internal technicians

- Enable scalable growth with consistent technical logic

- Reduce errors in documentation, naming, and programming

- Speed up implementation and internal validation

- Improve maintenance and traceability of changes

General Benefits

- 50% less time

In searching and diagnostics

Regulations

Better compliance with standards and regulations

Errors

Fewer errors and production stoppages

Full security

Full security, in the cloud or on-premise